Trusted 1.2311 Supplier Since 1997

For over two decades, we have been a trusted supplier of 1.2311 tool steel, serving industries worldwide with high-quality materials. Whether you are in the mold-making, automotive, or plastic injection industry, you need a reliable steel supplier who understands your needs and delivers premium-quality products.

What is 1.2311 Tool Steel?

1.2311 tool steel, also known as P20, is a pre-hardened plastic mold steel with excellent machinability, toughness, and wear resistance. It is widely used in the plastic mold industry due to its ability to resist deformation and cracking under high temperatures and pressure.

Key Properties of 1.2311 Steel

| Property | Value |

|---|---|

| Hardness (HRC) | 28-33 |

| Density | 7.85 g/cm³ |

| Yield Strength | ~850 MPa |

| Tensile Strength | ~1100 MPa |

| Thermal Conductivity | 29 W/m-K |

| Machinability | Excellent |

| Weldability | Good |

| Polishability | High |

Why Choose Us as Your 1.2311 Supplier?

1. Over 25 Years of Experience

Since 1997, we have specialized in supplying high-quality 1.2311 tool steel to global customers, building a reputation for reliability and expertise.

2. High-Quality Standards

We adhere to strict quality control processes, ensuring that every piece of steel meets international standards such as DIN, ASTM, and AISI. Our steel is rigorously tested for chemical composition, hardness, and mechanical properties before delivery.

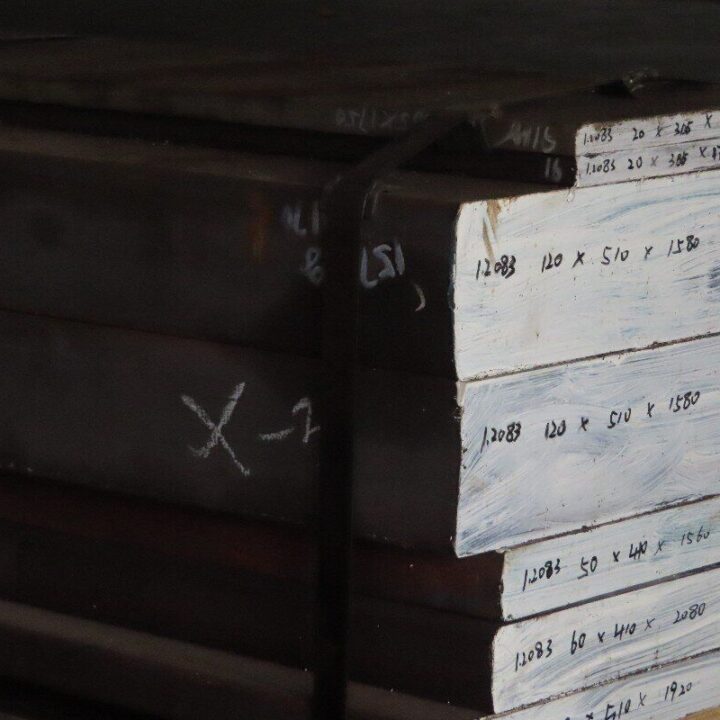

3. Large Stock Availability

We maintain a ready stock of 1.2311 steel in various sizes and forms, including round bars, flat bars, and blocks, allowing us to meet urgent customer demands without delays.

4. Competitive Pricing

With a strong supply chain and efficient logistics, we provide affordable pricing without compromising quality. Whether you need a small quantity or bulk orders, we offer cost-effective solutions tailored to your budget.

5. Fast & Secure Delivery

We ensure prompt shipping to any part of the world through trusted logistics partners. Our steel is carefully packaged to prevent damage during transit.

6. Technical Support & Customization

Our team of steel experts provides technical consultation on material selection, machining, and heat treatment to optimize your production process. We also offer cutting, milling, and custom-size services.

Contact Us for Your 1.2311 Steel Needs

📧 Email: [email protected]

📱 WhatsApp: +8613642825398

We are committed to providing the best quality steel at the most competitive prices, ensuring your projects run smoothly and efficiently.

FAQs

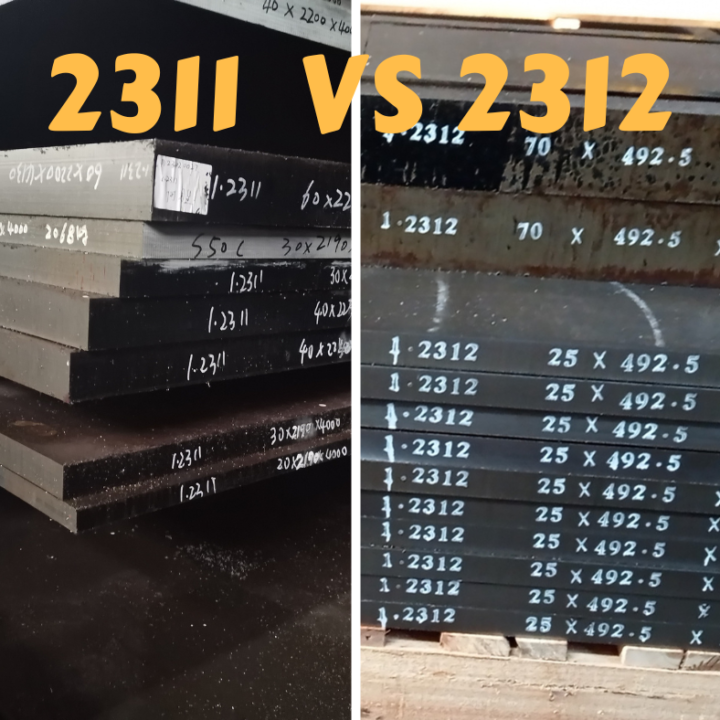

1. What is the difference between 1.2311 and 1.2312 steel?

1.2312 is a modified version of 1.2311 with added sulfur to improve machinability. However, it has slightly lower polishability and toughness.

2. Can 1.2311 steel be hardened further?

Yes, it can be hardened up to 52 HRC through heat treatment, but it is usually supplied in a pre-hardened condition to reduce processing costs.

3. Is 1.2311 suitable for high-temperature applications?

While it has good thermal stability, it is not ideal for extreme heat exposure. H13 steel is a better option for high-temperature applications.

4. How should I maintain 1.2311 steel molds?

Regular cleaning, lubrication, and controlled cooling help prolong the lifespan of 1.2311 steel molds and prevent premature wear.

5. Do you offer custom-cut sizes for 1.2311 ?

Yes! We provide custom cutting and machining services to meet your specific project requirements.