How does 1.2311 mould steel compare to other mold steel grades?

1.2311 mould steel, also known as P20 steel, is a versatile and widely used pre-hardened steel for making plastic molds and injection molds. It belongs to the group of low-alloy tool steels and is characterized by its excellent machinability, good polishability, and high wear resistance.

1.2311 mould steel, also known as P20 steel, is a versatile and widely used pre-hardened steel for making plastic molds and injection molds. It belongs to the group of low-alloy tool steels and is characterized by its excellent machinability, good polishability, and high wear resistance.

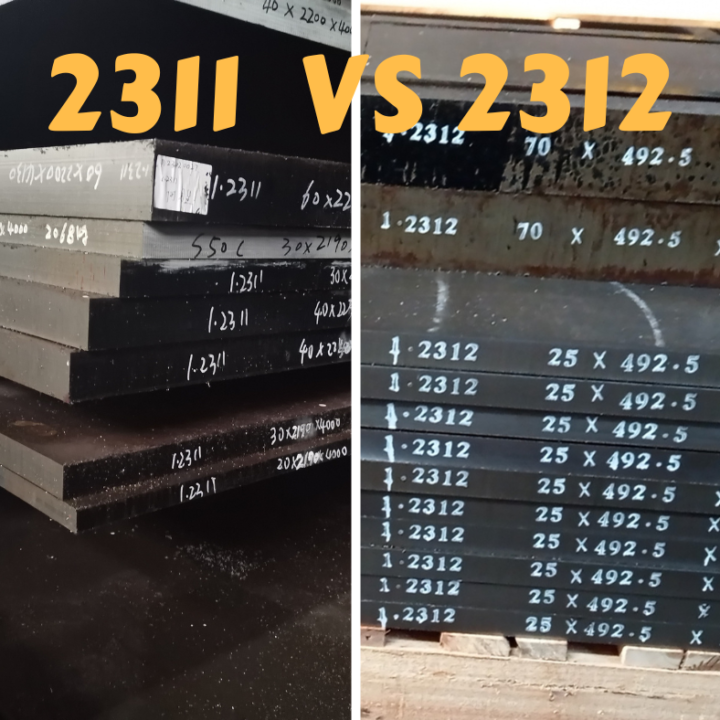

Comparing 1.2311 Mould Steel to Other Mold Steel Grades

- Hardness and Toughness: Compared to other mold steel grades, 1.2311 steel offers a balanced combination of hardness and toughness. While it may not be as hard as some high-end mold steels, its toughness makes it suitable for applications requiring resistance to impacts and stresses during the molding process.

- Machinability: 1.2311 mould steel is known for its excellent machinability, allowing for easy shaping and machining of molds with intricate designs. In contrast, some higher hardness mold steels may pose challenges in terms of machinability, requiring specialized equipment and processes.

- Polishability: 1.2311 steel exhibits good polishability, enabling manufacturers to achieve fine surface finishes on molded parts. This feature is essential for applications where aesthetics and surface quality are crucial. However, certain higher hardness mold steels may offer superior polishability, depending on specific requirements.

- Wear Resistance: While 1.2311 steel boasts excellent wear resistance, especially considering its pre-hardened state, some premium mold steels may offer even higher levels of wear resistance. These high-end mold steels are typically reserved for applications demanding extreme durability and prolonged tool life under harsh molding conditions.

- Cost and Availability: One significant advantage of 1.2311 mould steel is its cost-effectiveness and widespread availability compared to certain high-end mold steel grades. This makes 1.2311 steel a preferred choice for manufacturers looking to balance performance with cost efficiency without compromising on quality.

- Application Specificity: Different mold steel grades are tailored to specific applications and requirements. While 1.2311 steel caters to a broad range of molding applications, including automotive, consumer goods, and medical devices, certain specialized mold steels may offer unique properties optimized for specific industries or molding processes.

Applications of 1.2311 Mould Steel

1.2311 mould steel finds extensive applications across various industries, including:

- Automotive: Used for manufacturing automotive parts such as bumpers, dashboards, and interior trim components.

- Consumer Goods: Utilized in the production of consumer goods like kitchenware, toys, and electronic housings.

- Medical Devices: Employed for creating medical device components such as syringe barrels, IV connectors, and surgical instruments.

- Packaging: Ideal for producing packaging materials such as caps, closures, and containers.