1.2312 VS 1.2311

When it comes to choosing the right steel for a project, understanding the specifics of different types can make a significant difference in the quality and performance of the final product. Two commonly compared types of steel are 2312 and 2311. In this comprehensive guide, we’ll dive into the primary differences between these two types of steel, including their composition, properties, applications, and more.

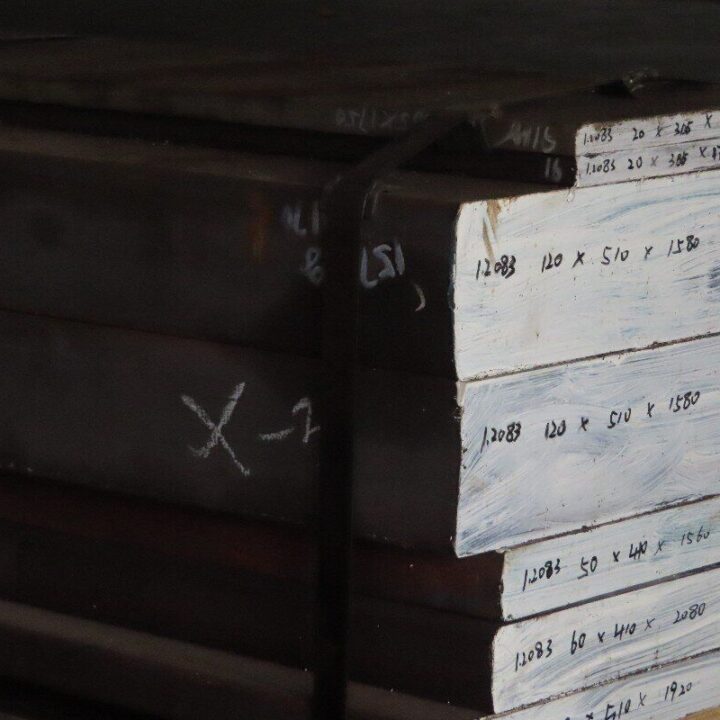

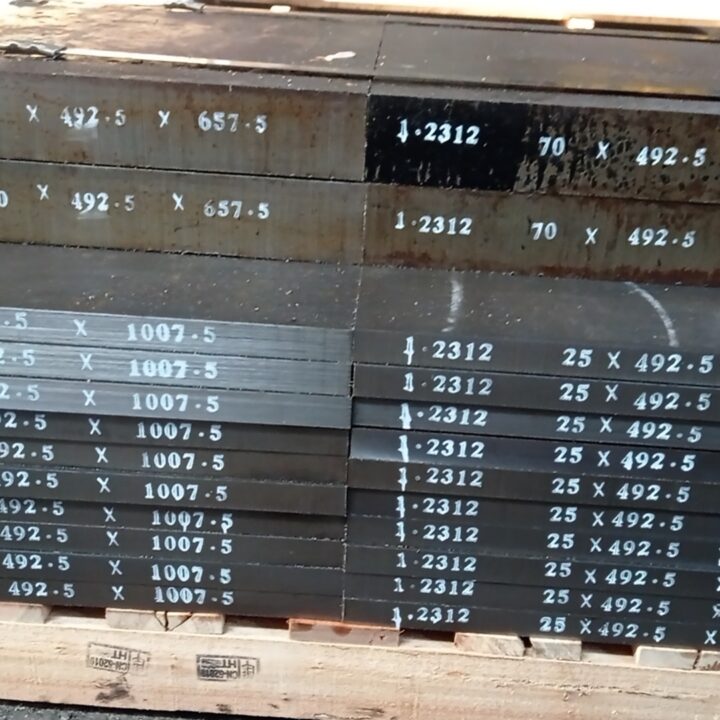

Understanding 2312 Steel

2312 steel, also known as 40CrMnMoS8-6, is a free-cutting steel often used in the manufacturing of plastic molds. This type of steel is particularly valued for its ease of machining due to the addition of sulfur, which improves its machinability.

Here’s the chemical composition table for 1.2312 steel:

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.35 – 0.45 |

| Silicon (Si) | 0.20 – 0.40 |

| Manganese (Mn) | 1.30 – 1.60 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | 0.05 – 0.10 |

| Chromium (Cr) | 1.80 – 2.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

Understanding 2311 Steel

2311 steel, known as P20 steel, is another type of alloy steel widely used in the manufacturing of plastic molds. However, it doesn’t contain sulfur, which means it has different properties compared to 2312 steel.

Here’s the chemical composition table for 1.2311 steel :

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.35 – 0.45 |

| Silicon (Si) | 0.20 – 0.40 |

| Manganese (Mn) | 1.40 – 1.60 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 1.80 – 2.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

Comparing 2312 and 2311 Steel

To better understand the differences between 2312 and 2311 steel, let’s compare their key aspects side by side.

| Aspect | 2312 Steel | 2311 Steel |

|---|---|---|

| Composition | Carbon: 0.4%, Chromium: 1.5%, Molybdenum: 0.2%, Sulfur: 0.07% | Carbon: 0.4%, Chromium: 1.9%, Molybdenum: 0.2%, No Sulfur |

| Hardness | 30 HRC | 30 HRC |

| Machinability | High (due to sulfur) | Moderate |

| Toughness | Moderate | High |

| Common Applications | Plastic molds, precision parts | Plastic molds, die casting |

Why Choose 2312 Steel?

- Ease of Machining: If your project requires extensive machining and fine detail, 2312 steel is an excellent choice due to its enhanced machinability.

- Cost Efficiency: The easier machining process can lead to lower production costs and faster turnaround times.

Why Choose 2311 Steel?

- Higher Toughness: For applications where the mold will experience higher levels of stress and needs to be more durable, 2311 steel is preferable.

- Longer Lifespan: The absence of sulfur means 2311 steel tends to be less brittle, contributing to a longer lifespan in demanding applications.

Conclusion

Choosing between 2312 and 2311 steel depends on the specific requirements of your project. If you need a steel that is easy to machine and cost-effective for producing detailed parts, 2312 steel is an excellent option. On the other hand, if your project demands higher toughness and durability, 2311 steel would be the better choice.

For further inquiries or to discuss your specific needs, feel free to reach out to us at Dongguan Otai Special Steel. We are always here to help you make the best choice for your project. Contact us via email at [email protected] or by WhatsApp at +8613642825398.