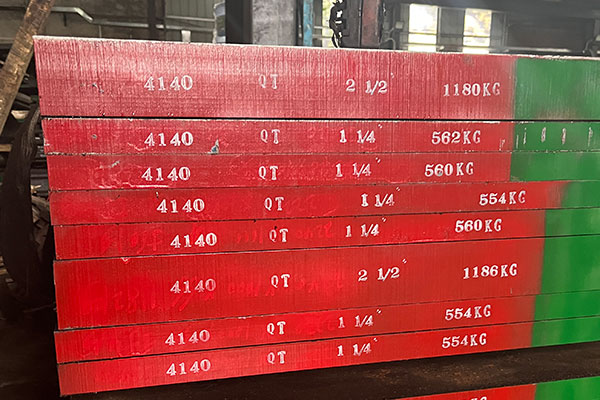

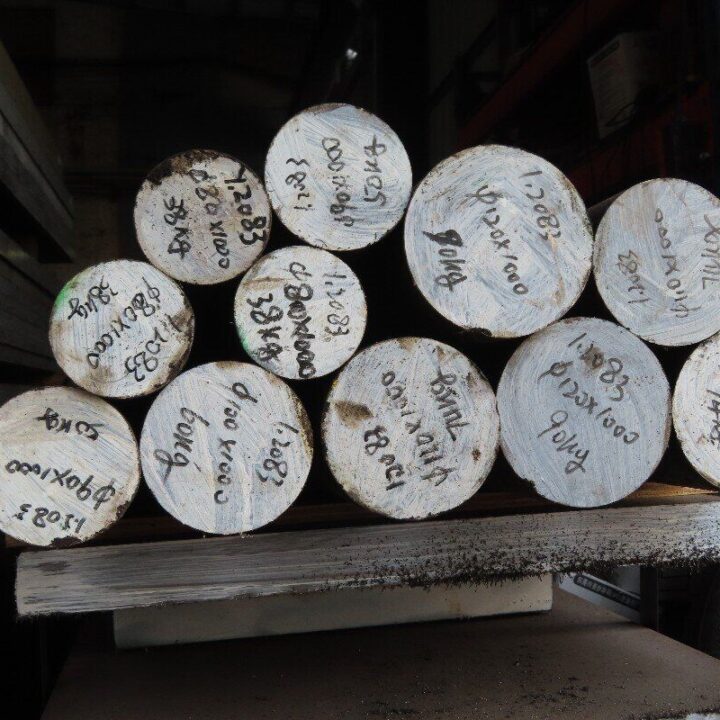

Steel is the backbone of modern industry, and among the numerous steel grades available, 4140 steel stands out due to its excellent properties and versatile applications. If you’re looking to dive deep into the world of 4140 alloy steel, you’re in the right place. Whether you’re an engineer, a manufacturer, or simply someone interested in high-performance materials, this comprehensive may will help you understand why 4140 might be the perfect choice for your next project.

What is 4140 ?

4140 steel is a chromium-molybdenum alloy steel known for its toughness, high fatigue strength, and abrasion and impact resistance. It is widely used in the manufacturing of various industrial components due to its excellent mechanical properties and versatility. It’s often referred to as “Chromoly” steel, thanks to its two main alloying elements: chromium and molybdenum.

Chemical Composition of 4140 alloy Steel

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.38-0.43 |

| Chromium (Cr) | 0.80-1.10 |

| Manganese (Mn) | 0.75-1.00 |

| Molybdenum (Mo) | 0.15-0.25 |

| Silicon (Si) | 0.15-0.30 |

| Sulfur (S) | 0.040 max |

| Phosphorus (P) | 0.035 max |

Mechanical Properties of 4140

| Property | Value |

|---|---|

| Tensile Strength | 655 MPa (min) |

| Yield Strength | 415 MPa (min) |

| Elongation | 20% (in 50mm) |

| Hardness (Brinell) | 197 – 237 HB |

Comparison with Other Steel Grades

| Property | 4140 Steel | 1045 Steel | 4340 Steel |

|---|---|---|---|

| Tensile Strength | 655 MPa | 570 MPa | 745 MPa |

| Yield Strength | 415 MPa | 310 MPa | 470 MPa |

| Hardness (Brinell) | 197 – 237 HB | 170 – 210 HB | 217 – 248 HB |

| Toughness | High | Moderate | Very High |

| Heat Treatability | Excellent | Limited | Excellent |