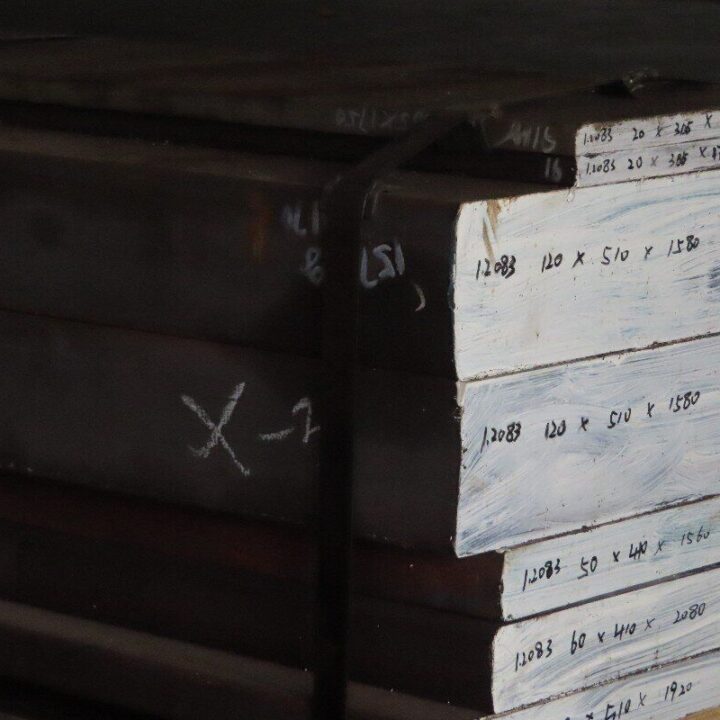

Today, we did a pre-delivery inspection and found that one piece 1. 2379 round bar had crack on the surface. Why is this?And how to avoid crack?

Material Quality:

Non-Metallic Inclusions: Presence of impurities such as oxides or sulfides can create weak spots that lead to cracks.

Segregation: Uneven distribution of alloying elements can cause localized weaknesses.

Heat Treatment:

Improper Quenching: Rapid cooling can induce thermal stresses, leading to surface cracks.

Inadequate Tempering: Insufficient tempering can result in residual stresses and surface brittleness.

Forging and Rolling:

Insufficient Forging: Inadequate working of the steel can leave internal stresses that surface as cracks.

Improper Rolling Temperatures: Rolling at incorrect temperatures can cause thermal stresses and cracks.

Surface Contamination:

Foreign Particles: Contaminants on the surface during processing can create initiation points for cracks.

Oxidation: Oxidation during heating can lead to surface weakening.

How can we avoid Crack?

As a stockist,Otai special steel , it is difficult for us to improve this problem from the production process, but we can choose high-quality mills for you, such as Baosteel, Dong bei Steel, Fushun Steel, Tiangong, etc.

Use high-quality raw materials with minimal impurities.

Conduct thorough chemical analysis and non-destructive testing (e.g., ultrasonic testing) to detect internal defects before further processing.

Perform regular inspections at various stages,like after production,delivery to our stock and before delivery , to identify and rectify defects early.

We can supply stable and good quality steel,If you have any commons,please contact us to discuss.

Email: [email protected] ; whatsapp: +86 136 4282 5398