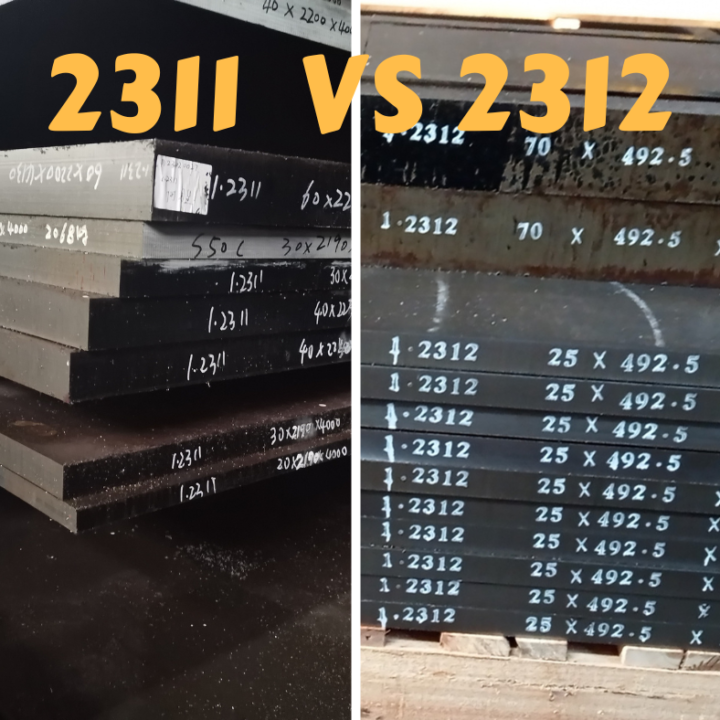

Steel materials play a crucial role in various industries, and when it comes to tools and molds, P20, 1.2311, and 1.2312 are among the top choices. Let’s delve into a comparison of these three steels to understand their properties and applications better.

Learn more details in our web.

Introduction to P20, 1.2311, and 1.2312 Steels

P20 Steel: P20 is a versatile low-alloy tool steel known for its excellent machinability and polishability. It’s commonly used in plastic injection molds due to its ability to maintain shape and form under high stress.

P20 Steel: P20 is a versatile low-alloy tool steel known for its excellent machinability and polishability. It’s commonly used in plastic injection molds due to its ability to maintain shape and form under high stress.- 1.2311 Steel: Also known as P20, 1.2311 is a pre-hardened steel characterized by its good toughness and machinability. It’s widely used for plastic molding applications where high precision and surface finish are required.

- 1.2312 Steel: 1.2312 is similar to 1.2311 but offers slightly higher hardness and better dimensional stability. It’s often preferred in applications where a higher level of wear resistance is necessary.

Comparison of Properties:P20,1.2311,1.2312

Let’s compare the key properties of these steels:

| Property | P20 Steel | 1.2311 Steel | 1.2312 Steel |

|---|---|---|---|

| Hardness (HRC) | 28-32 | 28-32 | 29-35 |

| Tensile Strength (MPa) | 1050-1350 | 1050-1350 | 1080-1280 |

| Yield Strength (MPa) | 950-1150 | 950-1150 | 1000-1150 |

| Density (g/cm³) | 7.80 | 7.80 | 7.85 |

Key Observations:

- Hardness: P20 and 1.2311 exhibit similar hardness levels ranging from 28 to 32 HRC, while 1.2312 offers slightly higher hardness, ranging from 29 to 35 HRC. This makes 1.2312 more suitable for applications requiring higher wear resistance.

- Tensile Strength: All three steels demonstrate comparable tensile strength, ensuring reliable performance under tension.

- Yield Strength: The yield strength of P20, 1.2311, and 1.2312 falls within a similar range, ensuring structural integrity under load.

- Density: While P20 and 1.2311 share the same density of approximately 7.80 g/cm³, 1.2312 has a slightly higher density of 7.85 g/cm³.

Conclusion: P20,1.2311,1.2312

In conclusion, P20, 1.2311, and 1.2312 steels are all excellent choices for tooling and molding applications. The choice between them depends on specific requirements such as hardness, wear resistance, and dimensional stability. Understanding these differences is crucial for selecting the most suitable material for your application.

FAQs

1. Which steel is best for plastic injection molding?

- P20 and 1.2311 steels are widely used for plastic injection molding due to their excellent machinability and polishability.

2. Are these steels suitable for high-temperature applications?

- While they offer good performance in standard operating conditions, specialized high-temperature applications may require alternative materials.

3. Can these steels be heat treated for further hardness?

- Yes, these steels can undergo heat treatment processes to achieve desired hardness levels.

4. What factors should I consider when choosing between these steels?

- Factors such as hardness requirements, dimensional stability, and wear resistance should be considered when selecting the appropriate steel for your application.

For further inquiries or assistance, please feel free to contact us at [email protected] or via WhatsApp at +8613642825398. We’re here to provide expert guidance and support for all your steel needs.