At Otai, we pride ourselves on our commitment to quality and precision in the world of steel. Specializing in top-grade tool steel and alloy steel, we cater to a wide range of industrial needs, offering an array of specialized steel grades tailored for various applications.

Our product line includes some of the industry’s most sought-after steel grades:

- M2 (1.3343): Renowned for its superior strength and durability, ideal for cutting tools and drill bits.

- D2 (1.2379): Known for its high wear resistance, perfect for long-lasting tooling applications.

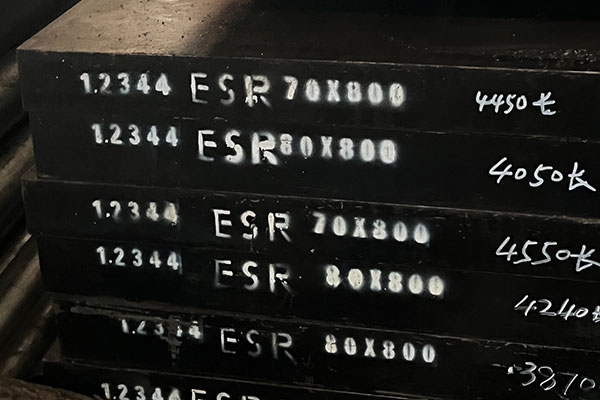

- H13 (1.2344): Exceptional hot work characteristics, widely used in die-casting and molding.

- O1 (1.2510): Offers excellent hardening capabilities, ideal for intricate tooling.

- P20 (1.2311): Versatile and easy to machine, commonly used in plastic molds.

- 4140 (42CrMo4) and 4340 (34CrNiMo6): Highly versatile alloys known for their strength and toughness, used in a variety of mechanical applications.

HIGH SPEED STEEL

High-speed steel is a group of tool steel alloys renowned for their ability to cut through materials at much higher speeds than traditional high-carbon steels, which were previously common in cutting tools. This advanced capability has earned them their distinctive name.

The very common steel high speed grades are

M2 (1.3343), M35 (1.3243), M42 (1.3247), T1 (1.3355), M50 etc.

HOT WORK TOOL STEEL

Hot work tool steels are engineered to perform optimally in high-temperature environments. They are characterized by their robustness, resistance to wear, and ability to maintain strength and durability under challenging conditions.

In ASTM A681 standard, there are “H” Hot Work Tool Steel Series from H. Like H10,H11, H12, H13, H14,H19,H21 H22,H23,H24,H25,H26, H42 Steel. The most popular one is H13 (1.2344) and H11 (1.2343) steel.

COLD WORKS TOOL STEEL

According to the ASTM Steel standard, the main categories of Cold Work Tool Steel include the “W” series, which hardens with water, the “O” series which hardens in oil, the “A” series which is a medium alloy that air hardens, and the “D” series known for its high carbon and high chromium content.

Examples of steel grades include: W1, W2, W5; O1 (DIN 1.2510), O2 (DIN 1.2842), O6, O7; A2 through A11; and AISI D2 (DIN 1.2379), AISI D3 (DIN 1.2080), D4, D5, D7, among others.

PLASTIC MOLD STEEL

Plastic mold steels are typically used in the direct fabrication of plastic molds. These steels are pre-tempered to a hardness level of 28-36 HRC before molding, which aids in minimizing the risk of deformations and cracking that could occur from heat treatments applied later on.

Popular plastic mold steel grades are P20 (1.2311), P20+S (1.2312), P20+Ni (1.2738), 420 (1.2083), 1.2085, NAK80, S136 etc.

ENGINEERING ALLOY STEEL

Alloy steel for engineering industries is in very large demand. We supply those top-selling steel grades, SAE 4140 (42CrMo4), SAE 4340 (34CrNiMo6), SAE 8620, 34CrNiMo6 (1.6582), 18CrNiMo7-6 (1.6587) etc.

CARBON STEEL

Carbon steel is widely used for lots of general applications. We supply DIN C45 (SAE 1045, JIS S45C), C20 (SAE 1020, JIS S20C).